PackMach Asia Drinktec 2025 exhibitor highlights Day 1

PackMach Asia Expo and drinktec India, taking place in Mumbai from 13–15 November and jointly organised by Messe Muenchen India and IPMMI, continued to highlight innovations across the packaging and processing value chain

14 Nov 2025 | 66 Views | By Sai Deepthi P

PackMach Asia Expo and drinktec India opened with a strong mix of packaging and processing innovations, as exhibitors showcased solutions spanning sustainability, coding, flexible packaging and liquid nitrogen dosing. The show floor reflected a clear industry shift towards material efficiency, regulatory-ready formats and next-generation machinery designed for both domestic and global markets. Here are a few highlights from exhibitors on Day 1

Dr Bio

Dr Bio drew steady interest at the show with its range of compostable and biodegradable products designed to replace conventional plastics across food, retail and daily-use categories. The company, represented by Surendra Oberoi, said its portfolio is built on PLA and cornstarch-based natural polymers that decompose within six months in landfill conditions. The products carry approvals from CPCB. “If you throw our products in the environment, they fully disintegrate in one year. One year is the maximum time.” says Oberoi.

Dr Bio is manufacturing cling films, stretch films and shrink films in addition to cutlery and packaging formats, with all products certified food grade. Oberoi highlighted that the lower melting point of these materials compared to LDPE or PP makes them incompatible with high-heat use, but emphasised their safety advantages, particularly in scenarios where plastic items may come in contact with warm food or beverages.

The company is positioning its compostable products as direct replacements for single-use plastics across F&B, retail and household consumption, with increasing traction from brands looking to transition away from petroleum-based materials.

Greenplas Tech

Gurgaon-based Greenplas Tech is yet another company with a portfolio focussed on compostable products. Greenplas presented its biodegradable portfolio, comprising cornstarch-based films and straws. The company operates two manufacturing units in Imrana, Rajasthan, and supplies straws for tetra-pack beverages to brands including Haldiram’s, Fresca, Praan Beverages and Dabur. It also supplies compostable films and bags to organisations such as AIIMS Jodhpur, AIIMS Delhi, Air India and various nursery and forestry departments.

The company has invested around INR 25-crore in plant and machinery for its compostable line. Greenplas Tech imports its cornstarch-based raw material and produces products that decompose fully within 180 days in soil, without harming soil organisms. Its garment-grade films are gaining traction in the apparel industry, while compostable garbage bags remain a major growth category.

At the show, the company said it had met more than 15 tetra-pack manufacturers on Day 1 alone, signalling strong demand for compostable alternatives as government procurement and private brands accelerate adoption of PLA-based materials.

Gable Top Pak

Gable Top Packaging showcased its plastic-free, premium cartons designed for natural mineral water. The company said its solution offers temperature stability superior to PET bottles, which can leach microplastics when exposed to heat. Its packaging is positioned as a sustainable alternative in line with recent FSSAI regulations allowing water to be served in non-transparent, eco-friendly formats.

The company markets two brands — Box Aqua and Kevla Niru — and distributes across India while also offering white-labelling services for restaurants and hospitality clients. According to a Raj Dedhia, sales and marketing head, the goal is to build a strong distribution network and raise awareness for gable-top formats as a viable, scalable option for water packaging.

This was the company’s first participation at the show. Early enquiries were encouraging, with the team optimistic about long-term adoption as consumers and businesses look for alternatives to both plastic and glass packaging.

Mehta Coding

Mehta Hi-Tech Industries was keen on selling the LaserJet 30C coder, a 30-watt laser system targeted at water bottling lines for expiry dates and serial markings. The company also displayed its LaserJet 30EF fibre-laser model for pharma and deodorant bottles.

Guruprasad Jadhav, sales executive, said the firm is focused on delivering reliable coding solutions for high-speed FMCG and pharmaceutical applications. With counterfeiting and product authenticity becoming industry-wide concerns, Mehta is currently conducting R&D on secure QR-code implementations to support traceability and product genuineness checks for pharmaceutical clients.

The company was expecting strong footfall at the event, particularly from bottling lines and manufacturers seeking to upgrade coding systems for compliance and speed.

Phoenix Label

Phoenix Label outlined their expanded portfolio, leveraging 13 years of experience in pressure-sensitive labels, adhesive labels and shrink sleeves for the pharma and beverages sector. The company is now scaling into BOPP wraparound labels — widely used in packaged drinking water — and laminate pouches, which it describes as a “vast opportunity” category.

Punit Soni, sales head, said the new investments include machines from Pelican and Kohli for flexo printing and pouch production. While no major customisation was required, the company emphasised the value of partnering with domestic machine manufacturers as part of its vocal for local strategy. Soni noted that the show provides strong visibility for Indian converters on an international platform, especially as demand for flexible packaging and wraparound labels continues to rise.

Shyam Plastic Machinery

Ahmedabad-based Shyam Plastic Machinery highlighted its PET blow moulding machines for beverages, edible oils, pharmaceuticals and liquor applications. The company's head S Kalaiarasan said it has supplied machines to 54 countries and is now exploring expansion into Russia and the United States.

Shyam Plastic Machinery emphasised machine reliability, build quality and service support as key differentiators. The company also noted that it regularly participates in drinktec and views this edition as a platform to connect with new brands and strengthen global partnerships, including potential collaborations with major beverage names.

The firm expects the event to help increase brand visibility and generate enquiries across both domestic and international markets.

Vacuum Barrier Systems (Liquid Nitrogen Dosing)

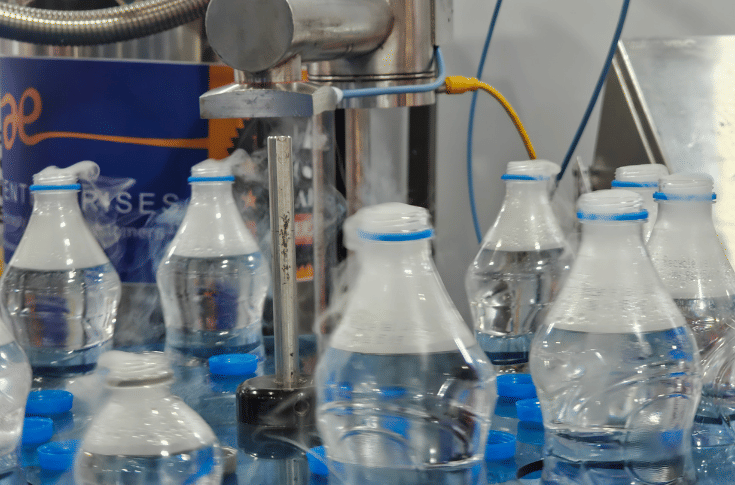

Vacuum Barrier Systems showcased its liquid nitrogen dosing technology, used across water, juice, wine and beverage lines. The system pressurises PET bottles by adding a controlled LN₂ drop before capping, allowing manufacturers to reduce resin usage while maintaining structural strength and stackability.

Meenal Potnis, internal sales, explained that in addition to improving rigidity, LN₂ dosing helps extend product shelf life. As the nitrogen evaporates instantly on contact, it displaces oxygen from the headspace, reducing oxidation in oxygen-sensitive products such as juices. The solution is food-grade and can be integrated into existing or new filling lines, with retrofittable units suitable for water and canning operations.

The company reported growing awareness of LN₂ technology in India over the past six to seven years and expects strong interest at the show as beverage manufacturers look for ways to improve packaging efficiency and reduce material consumption.