A peek into Nat Habit's ethos of sustainable commitment

Nat Habit, a beauty and wellness brand rethinks packaging through its material shifts from plastics to paper, shared in the company’s first Sustainability Impact Report

23 Dec 2025 | 1840 Views | By Abhay Avadhani

To put things in perspective, currently, Nat Habit nears INR 250-crore in annual run rate and expands across 3,000+ offline stores. It aims to set a new benchmark for how beauty brands in India can scale without compromising performance or purpose. What can transpire in terms of packaging for the beauty segment, Nat Habit aims to demonstrate that well with its tangible impact and growth.

For instance, Ayurveda is regarded as Nat Habit’s “business framework”. This includes its cold-pressed, kitchenstyle production methods, zero-pollution infrastructure, and plans to introduce compostable packaging and full-circle product lifecycle solutions.

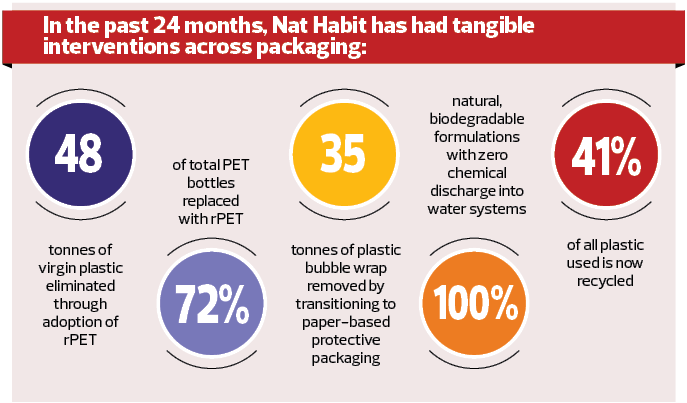

To exemplify, Nat Habit released its first Sustainability Impact Report on 2 December. Das believes reaching the INR 250-crore revenue mark was a meaningful inflection point for Nat Habit. Swagatika Das, cofounder and CEO at Nat Habit, expresses, “Over the last 24 months, we’ve transitioned 72% of our PET bottles to rPET, eliminated 35 tonnes of plastic bubble wrap, introduced biodegradable paper packaging, and strengthened zero-pollution manufacturing.”

Bold moves: Material shifts

Nat Habit operates in small, frequent batches instead of stockpiling. The company recently shifted to rPET. Das shares, “Despite India’s fragmented recycling ecosystem, our rPET supply remains stable because we maintain annual supply agreements with multiple certified suppliers, ensuring consistent quality. Additionally, limited rPET adoption in the food industry keeps availability high, allowing us to secure reliable, high-grade material for our packaging needs.”

The company also replaced 35 tonnes of bubble wrap with paper. This comes with the risk of causing breakage or damage during the last-mile deliveries. But Nat Habit claims to have stayed consistently low in damage. Das explains, “We developed our own paper bubble with the right GSM, cushioning structure and compression strength specifically for fresh, semi-delicate products.”

Before scaling it, Nat Habit tested it across multiple courier partners, routes and climate conditions. Das claims the outcome has been strong: The packaging holds its shape, absorbs impact well and protects the product without relying on plastic. So, she says, the shift to paper has not compromised product safety and has improved the company’s sustainability footprint.

“Transitioning a large share of our packaging to rPET demanded line changes, higher material costs and slower relaunches for some SKUs,” Das says. In the short term, it strained margins and operational flexibility. But, she continues, “It aligned with our long-term commitment to responsible beauty and strengthened the brand’s credibility.”

The methodology

Over the last 24 months, the company has also developed 100% natural, biodegradable formulations with zero chemical discharge into water systems. Das tells us, “Our formulations start with herbs and natural ingredients, which already lower the chemical load in our processes. On top of this, we operate a fully compliant effluent treatment plant at our factory.”

Talking about the manufacturing, she says, “Instead of shifting to large automated lines, we continue to operate small kitchen units that produce daily or on alternate days. This cold processed, low-energy, emission-free approach stays intact because we increase the number of units, not the batch size.” She accepts that it is slower, more intensive and operationally demanding, but it protects the purpose of the brand.

Das says that the freshness of the product is protected by the same discipline which Nat Habit uses online: Small batches, high frequency production and tight turnaround times from kitchen to shelf. For offline retail, the company works with smaller consignments, clear shelf life indicators, strict “first in first out” (FIFO) practices and close coordination with distributors.

Over the last 24 months, the company has also developed 100% natural, biodegradable formulations with zero chemical discharge into water systems

Zero-pollution infrastructure

Das claims that a meaningful portion of the company’s recent CapEx has gone into strengthening sustainability infrastructure. This includes pollution control systems, upgraded waste handling and energy efficient equipment that supports cold processing.

Alongside this, she says, “We have invested in more production units and supply chain upgrades that allow us to maintain fresh batch manufacturing at scale. For us, expansion and sustainability are intertwined, not sequential.”

Future plans

Das says that the company’s strongest differentiator is verifiable transparency at the batch level. She shares with the WhatPackaging? team, “We disclose ingredient sourcing, processing methods, freshness dates and compliance parameters in ways that can be audited. This goes far beyond generic claims like natural or clean.”

In the future, the company plans to introduce compostable packaging into its products. But, Das believes that the challenge lies in balancing environmental responsibility with product safety. She says, compostable materials vary widely in durability, shelf stability and certification clarity. “India also lacks widespread composting infrastructure, which means many packs labeled compostable may not actually decompose in real conditions,” Das continues.

All in all, Nat Habit is testing materials with reliable performance and clear certifications and will roll them out where the ecosystem supports their end-of-life journey.

Swagatika Das, co-founder and CEO at Nat Habit