Ecoleaf sparks shift towards sustainable metallic embellishment

Harald Jasper of Actega tells Noel D’Cunha how Ecoleaf redefines metallisation with on-demand, waste-free finesse

23 Dec 2025 | 1960 Views | By Noel D'Cunha

Noel D'Cunha (ND): Ecoleaf has been gaining significant attention. Could you explain what it is and what problem it is solving for the industry?

Harald Jasper (HJ): Ecoleaf sets a new standard in metallic embellishment that enables users to eliminate waste in metallic decoration and reduce the carbon footprint with more than eighty per cent. Traditionally, metallisation in labels and packaging relies on hot or cold foil stamping. These processes use a carrier film that is completely disposed of after transfer, which means that more than ninety to eighty per cent of the metal and 100% film never end up in the final product.

Ecoleaf turns that logic upside down. We use an ultra-thin layer of metallisation on a donor roller and only transfer what is needed for the image area. There is no carrier film that goes to waste. The remaining metal stays on the roller, ready for the next transfer. It is a clean, efficient, and sustainable process that delivers a similar visual effect as foil stamping, but with a fraction of the material.

ND: How does the Ecoleaf process actually work?

HJ: The principle is simple, but the chemistry and engineering behind it are complex. We start with a metallised donor roller that carries a mosaic layer of aluminium leaves. The printed substrate is first printed with a binder in the areas where the metallic effect is desired, we call it Trigger Image. The Trigger Image is cured after printing. When the donor roller comes into contact with the substrate, the metal only transfers to the Trigger Image pattern.

This selective transfer is key. The unused metal on the roller remains intact, so there is no waste film or spent carrier to dispose of. The roller is reloaded with new aluminium leaves in a closed-loop system, allowing continuous operation. The result is a stunning metallic fin ish that is indistinguishable from conventional foiling.

What makes Ecoleaf particularly attractive is its on demand nature. You are no longer limited by pre-manufactured foil rolls. The technology works “on-demand,” delivering high-impact metallic effects wherever they are needed and eliminating the necessity for PET carrier film and foil reels.

ND: What are the sustainability advantages compared with conventional metallisation?

HJ: In traditional hot or cold foiling, almost ninety per cent of the aluminium and polyester film becomes waste after transfer. Ecoleaf uses only the precise amount of metal needed for the image area, which reduces aluminium consumption by ninety to eighty percent and eliminates plastic carrier waste completely, 100 per cent.

From a carbon footprint perspective, the reduction is dramatic. Our ISO certified life-cycle assessment shows that Ecoleaf can cut CO2 equivalent emissions associated with metallic decoration by at least eighty per cent. Ecoleaf simplifies procurement, removes the logistical complexity of handling large rolls of foil, reduces shipping weight, and simplifies waste management.

Sustainability is not just about recyclability at the end of life. It is also about using fewer materials, reducing process energy, and creating smarter systems. That is exactly what Ecoleaf achieves.

Harald Jasper: Sustainable beauty is our contribution to the future. Ecoleaf delivers the superiority of metallisation without the burden of waste

ND: Does Ecoleaf require a change in print or finishing infrastructure?

HJ: That was one of our design priorities. Ecoleaf is designed to integrate easily into existing production environments. It can be installed as a modular unit, inline on narrow web presses, inline and offline on converting equipment like ABG.

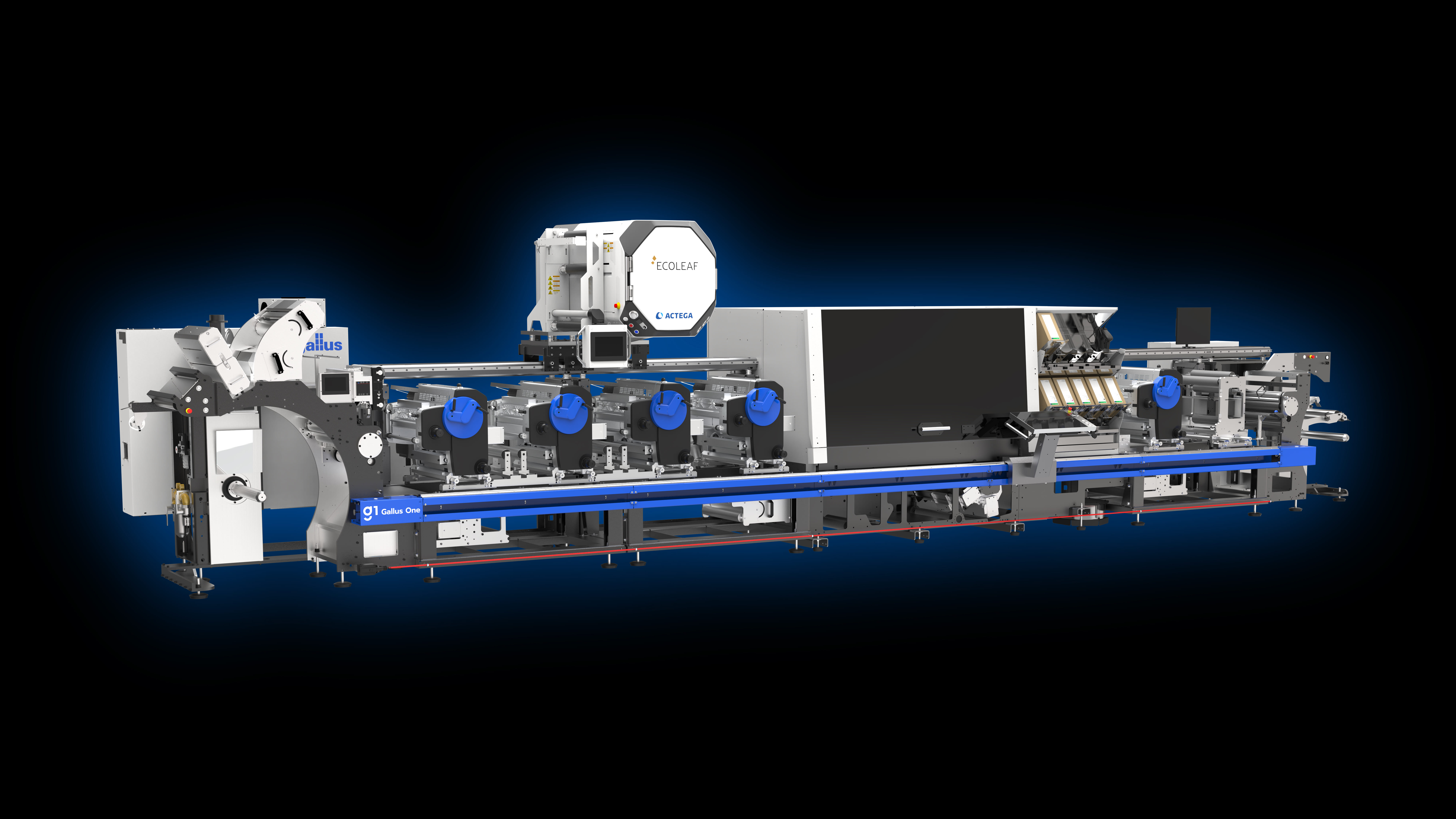

For converters already using Gallus or similar hybrid presses, for example, integration is straightforward. The Gallus Labelfire and Gallus One plat form are fully compatible with Ecoleaf. We have worked closely with the Gallus development team to ensure that print registration, curing, and adhesive compatibility are optimised.

It is also retrofittable. Many converters have existing finishing lines, and we designed Ecoleaf to fit within those workflows with minimal downtime. Installation is easy and operator training is simple.

ND: How does the visual quality of Ecoleaf compare with traditional foils?

HJ: That is one of the most important questions we receive from brand owners. The answer is that there is no compromise in quality. The metallic finish is crisp, bright, and fully reflective. Depending on the printing method used to print the Trigger Image, you can achieve high gloss, matte, and tactile effects to create multi-dimensional effects.

We can also combine metallic layers with varnishes or overprinting to create a rainbow of colours. In many cases, designers appreciate the creative freedom that Ecoleaf enables, because they are no longer restricted by foil colours, roll widths or mechanical limitations.

The visual result is virtually identical to conventional foil, and in some cases, it looks even better because of the very fine detail and tactile effects.

ND: What role have collaborations with companies like Gallus and All4Labels played in Ecoleaf’s development?

HJ: Partnerships are essential. Ecoleaf is not a standalone technology; it needs to work seamlessly within established printing ecosystems. Our col laboration with Gallus ensures that Ecoleaf increase efficiently with their hybrid press platforms. Together, we have vali dated colour management, curing systems, and workflow compatibility.

All4Labels, on the other hand, has been instrumental in validating Ecoleaf at scale. They are one of the world’s largest label converters, and their feedback has helped refine the system for high-volume production. By running Ecoleaf on multiple substrates and in different production environments, we confirmed its reliability and repeatability.

These collaborations also send a strong signal to the industry. When leading press manufacturers and converters adopt a technology, it gives brand own ers confidence that it is proven and commercially viable.

Harald Jasper, managing director of Actega Metal Print

ND: How does Ecoleaf align with broader regulatory and sus tainability goals, such as the EU Packaging and Packaging Waste Regulation (PPWR)?

HJ: Ecoleaf is perfectly aligned with the direction of PPWR. The regulation encourages material reduction, design for recycling, and lower environmental impact. Ecoleaf directly addresses all three.

Because there is no plastic carrier film, the metallised decoration no longer interferes with recycling streams. The applied metal layer is extremely thin; it does not hinder material recovery. From a compliance perspective, Ecoleaf meets the require ments for recyclability in both paper and film labels.

It also supports brand owners’ voluntary sustainability commitments. Many global brands have pledged to make their packaging recyclable, reusable, or compostable by 2030. Ecoleaf gives them a practical tool to achieve that without compromising aes thetics or performance.

ND: How is the technology being received by converters and brand owners?

HJ: The response has been very positive. Converters appreciate that they can offer a sustainable metallisation option without changing their press architecture. Brand owners see it as a way to keep superior packaging while meeting sustainability targets.

We have installations around the world, with more coming online every quarter. Many customers are integrating Ecoleaf as a premium decoration option for labels, cosmetics, and personal care packaging. In some cases, they are replacing foiling completely; in others, they are using it selectively for specific SKUs.

The key driver is that Ecoleaf combines environmental benefit with creative flexibility. It does not ask the market to choose between sustainability and design.

ND: Beyond labels, where else do you see Ecoleaf being applied?

HJ: While labels are the starting point, we are already seeing strong potential in laminated tubes and shrink sleeves. The technology is material-agnostic; as long as there is a printable adhesive surface, we can metallise it.

ND: What is the broader flexi ble packaging strategy at Actega, and how does Ecoleaf fit within it?

HJ: Actega’s strategy is to offer a complete portfolio of sustainable coatings, adhesives, and effect solutions for flexible packaging. This includes water based coatings, barrier systems, tactile finishes, and Ecoleaf, which adds to this comprehensive offering.

Ecoleaf is one pillar of a much larger sustainability roadmap. Our goal is to replace resource intensive processes with smarter, more efficient alternatives. For example, we are developing barrier coatings that can substitute for polyethene layers in paper packaging, improving recyclability.

In the long term, we want to provide converters with a tool box that lets them design packaging that is both functional and circular. Ecoleaf fits into that vision by addressing one of the most visible but least sustainable aspects of packaging, metallic decoration.

ND: Are there any specific challenges in implementing Ecoleaf at an industrial scale?

HJ: From an operational stand point, the system is straight forward. Once installed, it runs with minimal maintenance. The donor roller lasts for millions of impressions, and the metallisation material is refilled automatically.

The biggest challenge, honestly, is mindset. The industry is used to foiling, which has been around for decades. Ecoleaf requires a different way of thinking about how metallic effects are produced. But once converters experience the efficiency and sustainability benefits, adoption becomes an easy decision.

ND: How does Actega ensure colour consistency and visual quality across applications?

HJ: Consistency is critical, especially for brand colours and metallic finishes. The metallic layer can be overprinted or tinted to match brand-specific shades, giving designers full flexibility. With Ecoleaf, the flop, colour consistency, and Metamerism are better.

ND: Could you tell us more about Actega’s partnerships beyond Gallus and All4Labels?

HJ: We collaborate with several technology partners across the value chain, including press manufacturers, ink suppliers, and converters. We also engage with research institutes to develop next-generation barrier coatings and recyclability studies. Partnerships are essential because sustainability cannot be achieved in isolation. It requires collaboration between materials science, printing technology, and brand management.

ND: What does the future look like for Ecoleaf and Actega’s sustainable technologies?

HJ: We are still in the early stage of a significant transformation. Ecoleaf is proving that sustainability and aesthetics can coexist. The next step is scaling and diversification.

Beyond Ecoleaf, Actega continues to invest in sustainable chemistry. Our research pipe line includes compostable coatings, low-energy curing systems, and barrier technologies for circular packaging.

Our vision is that every decorative and functional element of a package can be produced in a sustainable way. That means no waste, minimal material, and full recyclability.

ND: Finally, how do you see the Indian market for technologies like Ecoleaf?

HJ: India is a dynamic market. The packaging industry is growing, and there is strong awareness about sustainability. At the same time, there is an incredible level of creativity in design and finishing.

Ecoleaf fits perfectly in that environment. It allows Indian converters to offer global quality metallic decoration while reducing waste. We are already in discussions with partners to bring Ecoleaf to India in a structured way.

Once the right local support and supply chain are in place, I believe adoption will be very fast. Indian brands are ambitious, and Ecoleaf provides them with a tool that combines a premium appearance with environmental responsibility.