Packaging water for a better future

As packaged water in PET bottles falls under scrutiny for plastic pollution, a new generation of Indian brands is making an impact with sustainable, paper-based carton packaging.

23 Dec 2025 | 406 Views | By Sai Deepthi P

The simple act of buying packaged water has a storied past. In its early days, packaged drinking water was a revolutionary convenience, initially serving as a luxury. In Europe and America, it offered the wealthy access to therapeutic spring water. Similarly, in India, Bisleri, one of the first brands, was exclusively sold in hotels until the late 1960s. Today, it is essential, unimaginable to travel without, be it Rail Neer at stations or bottles at motorway service areas. Just when you thought that packaging of water is at the fag end of its innovation cycle, now there are new entrants taking it one step further to make their packaging sustainable.

Yet, this convenience has created a crisis. Packaged water in PET bottles is now widely seen as the poster child for plastic pollution, turning a solution into a significant environmental problem. While brands like Bisleri's PET bottles are fully recyclable, the limited availability of recycled PET means few companies use it at scale, leading to bans on many campuses and in countries.

Water in a carton?

This growing environmental awareness has sparked innovation. A plastic ban on a US college campus inspired Rhea Raheja and Ishaan Nangia to found Impact Water.

“I saw how quickly that small change reduced waste and encouraged people to switch to better alternatives. At the same time, I noticed sustainable carton-packaged water brands were already becoming popular in the US,” says Nangia. The co-founders realised India needed a modern, convenient, and accessible sustainable alternative, but without the environmental cost of plastic.

Impact Water cartons are primarily made from FSC-certified paperboard, sourced from responsibly managed forests. The remaining layers consist of thin, food-grade polyethylene (PE) and a small amount of aluminum, forming protective barriers that keep the water safe, hygienic, and shelf-stable without preservatives. Nangia explains their focus:

“We ensure that the majority of our packaging comes from renewable sources, and we are actively working with partners to improve recycling systems so that every part of the carton can be recovered and reused. Our long-term goal is to increase the share of renewable materials in our packaging while exploring next-generation alternatives that push us closer to fully circular solutions.”

Driven by the need to replace plastic, the founders chose paper-based cartons as they reduce single-use plastic while remaining lightweight and practical. “It was important that our solution didn’t just look sustainable, but actually made a measurable impact.”

Another key player in this space is Gable Top Pak which has been exploring alternative packaging formats since 2021. During extensive travels, the team observed how innovatively water was being packaged across the world. The discovery of gable top cartons, traditionally used for dairy, instantly felt like the perfect match for the safe, sustainable, and premium water experience they envisioned for India.

A key decision that drove innovation in this space was also Bureau of Indian Standards (BIS) issuing a landmark notification in early 2024, allowing natural mineral water and packaged drinking water to be sold in opaque packaging formats such as multilayer paper-based cartons. Until then, regulations had mandated 70% transparency in water packaging, limiting innovations.

Gable Top Pak features brands such as Boxed Aqua, Kevala Niru, and Alkind Wtr. With a strong manufacturing base, each of their plants has a minimum production capacity of 8,00,000-packs per month. Its cartons are similarly constructed with a focus on sustainability: 74% renewable FSC-certified paperboard, 5% aluminum in the box structure for their water products, and the remainder being PE (polyethylene) and precision-engineered caps are imported to maintain global quality standards. Its brand Kevala Niru was created with the simple mission to "provide pure, safe, and trustworthy packaged drinking water while reducing plastic dependency."

Backbay cartons are FSC-certified with sugarcane-based caps

What the consumers say

For many Indian customers, carton-packaged water is a new experience. Some initially find it unusual not being able to see the water while drinking, but this hesitation quickly fades once they experience the quality and understand the environmental benefit. Most describe it as a small, everyday change with a big impact.

Impact Water is currently sold in 500-ml cartons to fit daily consumer habits in India. New formats are in the pipeline, including a 350-ml pack for events, weddings, and concerts, and a 750-ml pack for hotels and restaurants.

On the design front, the brand aims for a clean, modern, bold identity. Customers note that cartons are easier to carry, feel premium, stay cooler longer, and protect water from light exposure, which helps prevent loss of taste.

The cost factor, while a challenge, is not insurmountable.

“We have found that customers today are increasingly conscious of their choices. While sustainable packaging can cost more, many are willing to pay that premium. Younger consumers, in particular, actively seek brands that align with their values,” says Nangia. Impact Water positions itself between cheap plastic and expensive glass, offering a solution that is premium yet practical.

Gable Top Pak co-founder Geetanjali Gupta also echoes this sentiment, highlighting market hurdles: "Major barriers include higher costs, supply chain complexity, and competition from cheaper plastics. However, government regulations and rising consumer eco-awareness support strong future growth."

Kevala Niru’s sustainable carton packaging adds an approximate cost premium of around 10-20% compared to standard PET bottles. Despite this, Gupta asserts that "Clients are happy with the unique and attractive design of the bottle, which stands out despite its higher cost compared to plastic."

Interestingly, new demand for the convenient packaging is also being seen in sectors like the oil and soap industries.

Manufacturing and innovation

Impact Water is manufactured in India at a filling and sealing plant in Navi Mumbai. The fac tory has several steps in place to reduce its environmental footprint: minimising material waste, replacing plastic-based tapes, reusing cartons from B2B customers, and adopting lighter packaging to reduce fuel emissions. By 2027, the company plans to shift 100% of direct-sale deliveries to EV trucks.

The team has also experimented with compostable and biodegradable alternatives like polylactic acid (PLA) or moulded pulp.

"While promising, the current challenges lie in scalability, shelf-life, and infrastructure. Compostable materials break down with moisture, making them unsuitable for safely storing water," Gupta addresses the challenge of complete biodegradability due to the aluminium layer, noting that promising alternatives exist, including "bio-based barrier coatings and innovative polymer layers that maintain product protection while enabling easier recycling."

Gable Top’s own R&D is actively focused on developing high-barrier bio-based and polymer-only films. The company is working on bio-based barriers.

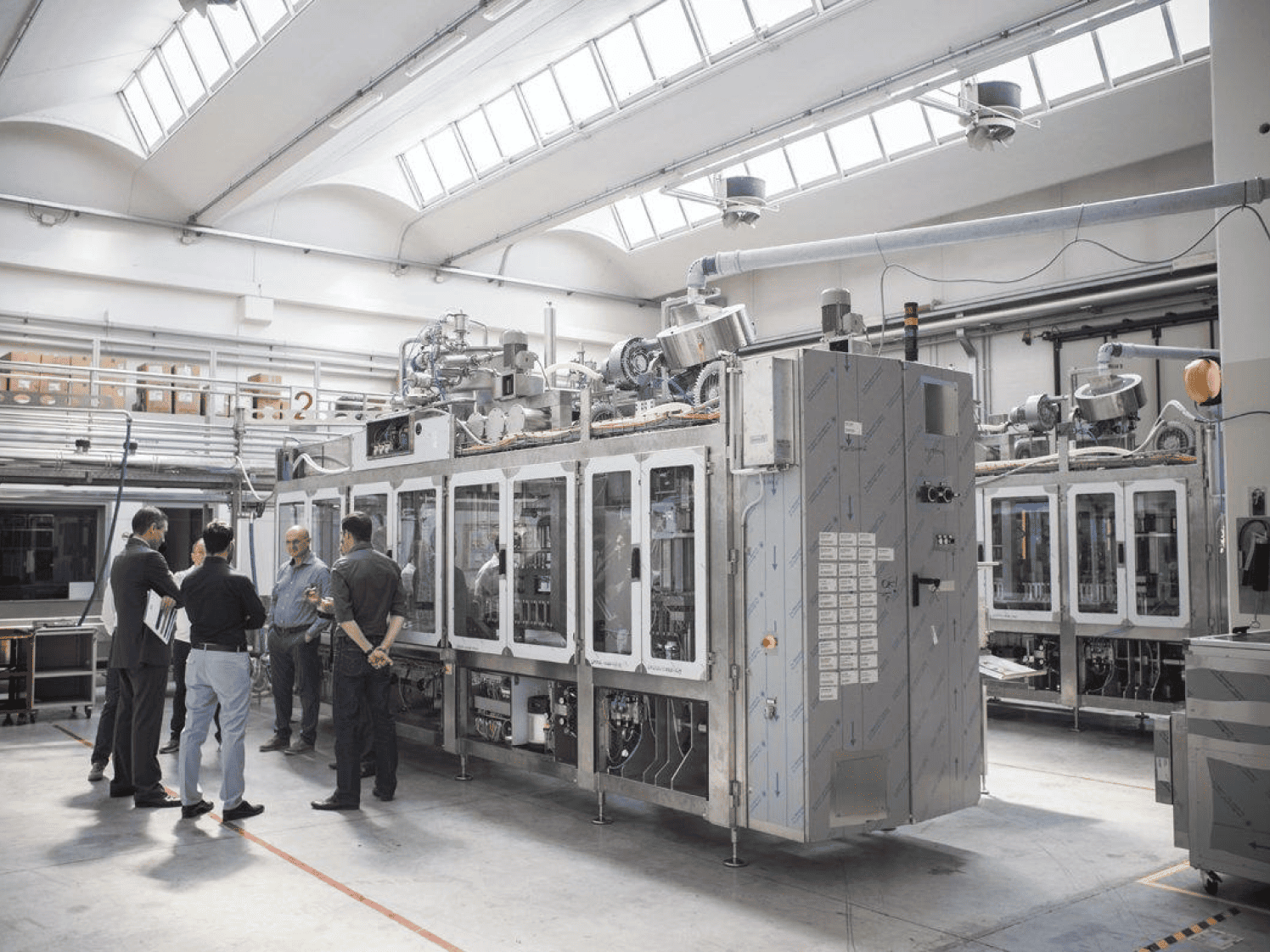

At Gable Top Pak, the water filling process is completely in-house using high-tech, automated machines that integrate carton forming, chamber sterilisation, liquid filling, top sealing, and capping in a single line, ensuring hygiene and safety. Gupta details the technology:

"The plant uses an automatic gable-top carton forming and filling line, typically made from stainless steel and controlled by programmable logic controller (PLC) systems. Maximum output is 1,200–6,000-cartons per hour, based on carton size and product. Our plant uses a fully automatic gable-top carton forming and filling machine."

For complete circularity, the company actively engages with several recyclers to establish an effi cient collection and recycling model for their multi-layer Kevala Niru cartons. Looking ahead, Gable Top Pak is focused on innovations such as new closures, fiber-based bar rier technologies, and reduced paper grammage to further lower environmental impact.

The global gable top packaging market at USD 5.1-billion in 2025, projected to reach USD 8.5-billion by 2035 at a CAGR of 5.3%

Industry ecosystem

The shift to cartons is being supported by the wider packaging industry. The Printmann Group, through its subsidiary Pakcellence, has entered the liquid packaging market with Gable Top cartons, offering a full value chain solution, including machine and substrate partnerships.

Their collaboration with Galdi, a leading provider of mid-capacity filling machines across Europe, the Middle East, Africa, and Southeast Asia, is pivotal. Galdi’s subsidiary, Fill Good, supports customised filling systems, enabling product innovation for new brands and startups. Galdi’s Gable Top machines can handle multiple formats (250-ml to 2,000-ml) with quick changeovers, allowing for high flexibility. They were instrumental in launching the first carton water in Italy, Greece, and Kosovo.

Even celebrity-backed brands are driving adoption. Backbay, launched by actor Bhumi Pednekar and her sister Samiksha, introduced Backbay Aqua Himalayan mineral water, which is enriched with electro lytes and packaged in FSC certified cartons with sugarcane-based caps.

The market outlook is strong. Future Market Insights estimates the global gable top packaging market at USD 5.1-billion in 2025, projected to reach USD 8.5-billion by 2035 at a CAGR of 5.3%.