Miraclon and W&H elevate partnership in Germany

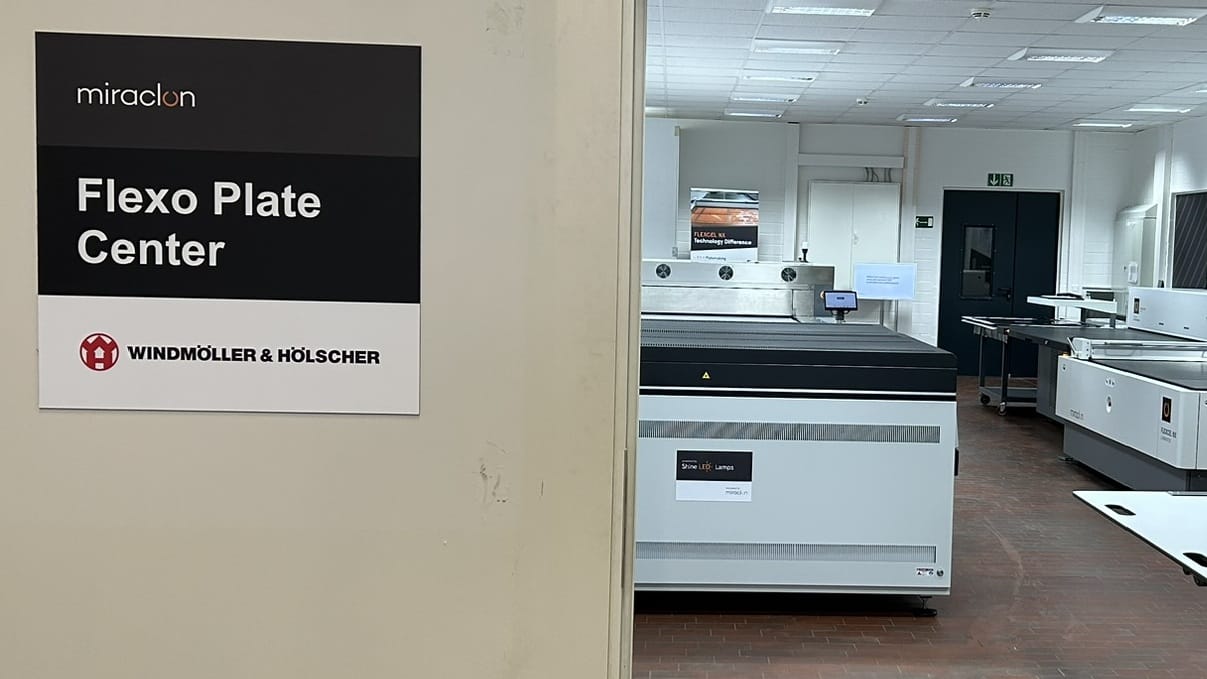

Miraclon has announced a reinforcement of its partnership with Windmoller & Holscher (W&H) with the installation of a new Flexcel NX Ultra 42 Solution at the W&H Technology Center in Lengerich, Germany.

17 Feb 2026 | 18 Views | By Jiya Somaiya

The upgrade provides a larger-format, water-processed platemaking solution, enabling W&H to demonstrate a broader range of realistic customer applications and press configurations for visitors.

The new system replaces the previously installed Flexcel NX Ultra 35 Solution. Its expanded capacity is set to showcase the full potential of modern flexo in a real-world environment, allowing converters to see a wider array of applications.

As per a Miraclon spokesperson, "Although the installation is in Germany, the move is relevant for the Indian flexo market." A substantial number of Indian customers who are considering the purchase of a CI Flexo press frequently visit the W&H Lengerich demo centre. The new installation ensures that all visitors—including those evaluating in-house plate making—will interact with the water-based processing device. This integration of the latest flexo plate preparation technology into the CI press demonstration process gives all visiting Indian converters a key touchpoint with the new equipment and its capabilities.

Frederik Petzold, the director, Technical Sales, Windmoller & Holscher said, “At W&H, our Technology Center plays a key role in showing converters how individual technologies come together to form an efficient and industrially scalable printing solution." He added, "The FLEXCEL NX Ultra 42 Solution allows for improved flexibility for wideweb printing, and the plate performance required to run highly controlled, data-driven press demonstrations."

Petzold added that the solution’s consistent multi-form plate surface patterning and stable ink transfer characteristics enable W&H to showcase its presses operating at optimal efficiency—highlighting wider process windows, faster stabilization on press, and the repeatable print quality customers expect when evaluating advanced flexo technologies.

Grant Blewett, the chief commercial officer at Miraclon, underscored the value of the collaboration. “Our collaboration with W&H remains a powerful platform to demonstrate the real-world impact of Flexcel NX Technology and modern flexo,” he stated. "The Flexcel NX Ultra Solution achieves the same proven on-press performance of the Flexcel NX System, with the added benefits of solvent-free and VOC-free platemaking that delivers consistent ink transfer, stable on-press behavior and highly predictable results. Seeing it in action at W&H provides a compelling example of how modern flexo delivers efficiency, sustainability, and production control for converters around the world."

To further support high-quality demonstrations, W&H has also incorporated a Glunz & Jensen FlexPose 420 ECDLF exposure unit, equipped with a Miraclon-innovated Shine LED Lamp Kit. The kit ensures stable, uniform UV output for highly consistent plate exposure, eliminating variability from aging mercury lamps.