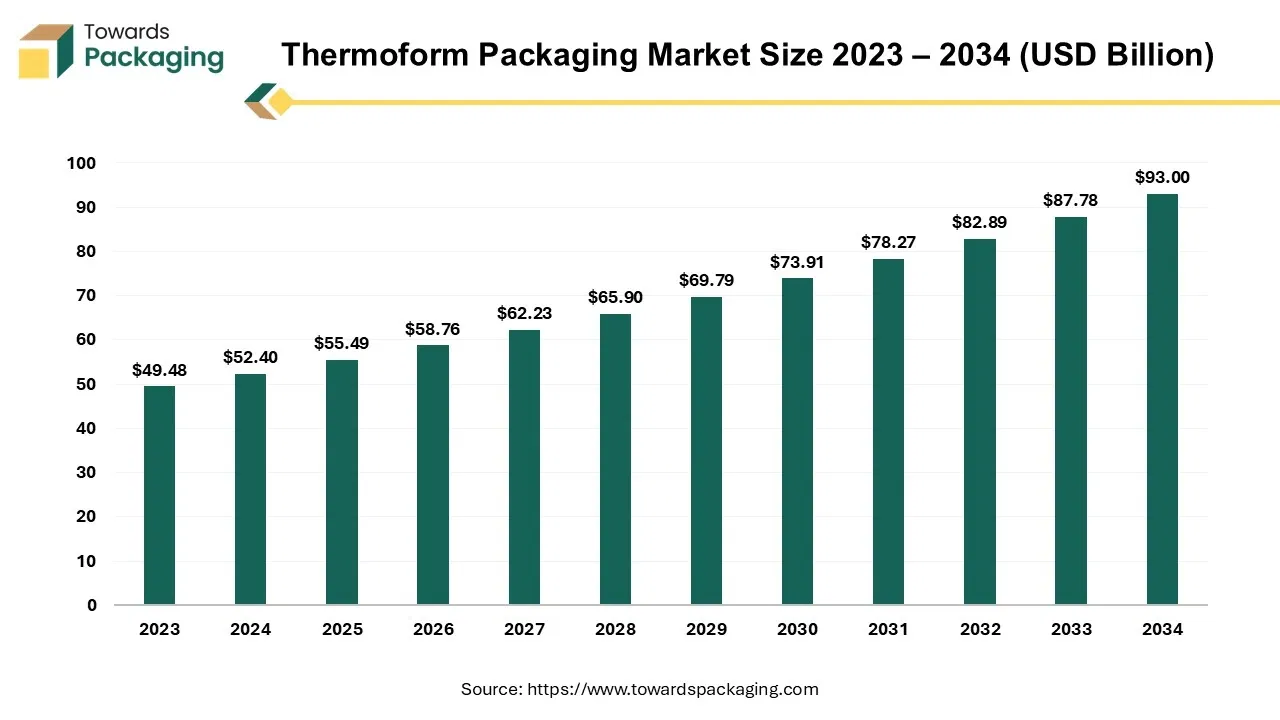

Thermoform packaging market to grow at 5.9% CAGR

The global thermoform packaging market which is valued at approximately USD 55-billion, is expected to nearly double and hit USD 93 billion by 2034, expanding at a 5.9% CAGR. A report by Towards Packaging.

12 Sep 2025 | 1140 Views | By Abhay Avadhani

A combination of versatility, sustainability, design innovation, and the adoption of technologies like AI and robotics are fueling this growth.

Thermoform packaging transforms a simple plastic sheet into tailored packaging solutions. Manufacturers create a wide spectrum of products—ranging from blister packs and clamshells to trays and containers.

This adaptability makes thermoforming the go-to choice for industries as diverse as food and beverages, pharmaceuticals, electronics, and retail. The process not only ensures product protection but also allows for visibility, making products appealing on store shelves.

Robotics and automation have found their way into thermoforming plants, elevating precision, speed, and efficiency. From material handling to packaging assembly, robots are a part of everything, bringing repeatability and cost effectiveness.

AI is another game-changer. Predictive maintenance reduces unexpected downtime, while real-time monitoring optimises production.

The conversation around thermoform packaging increasingly revolves around sustainability. Companies are actively pursuing lightweight designs, eco-friendly materials, and recyclable solutions. In Europe, the plastics industry has set bold goals—up to 60% recycling and reuse by 2030.

The US now recycles over 139-million pounds of PET thermoform packaging annually. These recycled materials are repurposed into new thermoforms that protect food, beverages, and other consumer goods

Coveris’s introduction of recyclable MonoFlex Thermoform in 2023 reflects the APAC’s growing commitment to eco-friendly innovation.

Companies are now using 3D modeling, virtual prototyping, and advanced printing technologies to produce packaging that is both functional and visually striking. For example, a bakery product showcased in a translucent PET clamshell, or a yogurt cup crafted from multilayer barrier films.

Thermoform fill-and-seal machines churn out cups, bowls, and trays with consistency and efficiency, meeting the sector’s high standards. For products like baby food, soups, and dairy items, multilayer films extend shelf life by keeping oxygen at bay.

Recent innovations, such as GEA’s 2023 launch of thermoforming technology for high-capacity packing of cheese and diced foods, demonstrates the industry’s adaptability.

From a materials perspective, PET leads the way, supported by C-PET for oven-ready meals, a-PET for bakery and confectionery, and rPET for sustainable packaging. Globally, PP witnesses over 30-million tonnes in demand annually across food, automotive, and consumer goods industries.

Some of the trends that the report highlights are robotics, real-time supply chain updates, biodegradable solutions and design innovation.