Chris Bradford: AkzoNobel delivers sustainability with coatings

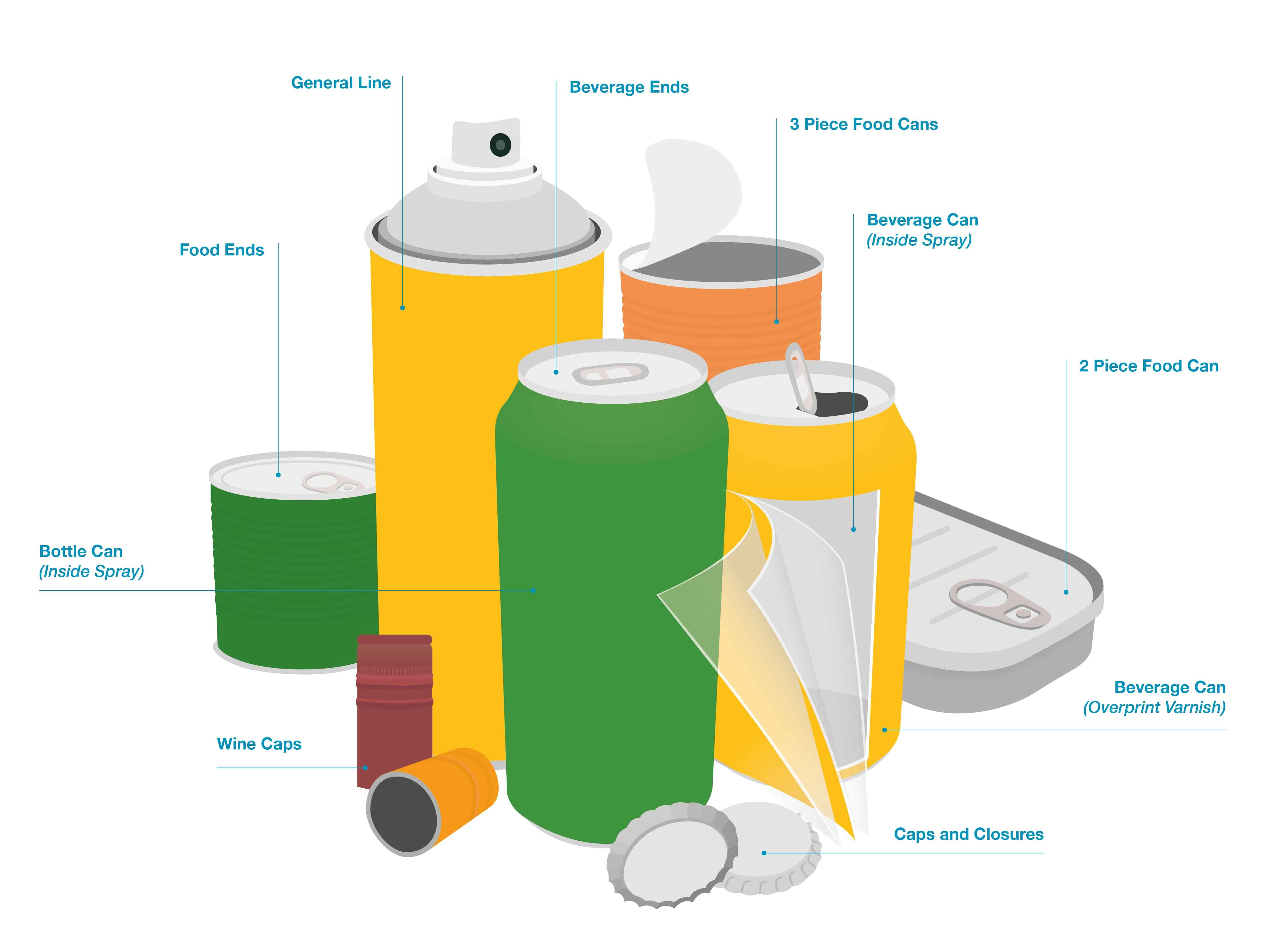

Two products in the AkzoNobel portfolio are popular. These are: the Aqualure 900, an internal water-based spray lacquer for aluminium beverage cans, and the Vitalure 330 – internal gold lacquer for processed food cans. Chris Bradford, the global marketing director for industrial coatings at AkzoNobel, talks to Abhay Avadhani about how coatings provide advantages over lamination

30 Jul 2024 | By Abhay Avadhani

Abhay Avadhani (AA): What is the update on the production of coatings on your front?

Chris Bradford (CB): Currently, we produce packaging coatings in India at our Thane plant. We are planning to add new product categories for manufacture at Thane like BPAni coatings and water-based overprint varnishes for beverage cans in the near future. Our aim is to ensure excellent service levels to our customers

AA: Do coatings offer barrier properties without harmful side effects?

CB: Internal can coatings are the barrier to protect the food content from metal and vice versa. Our coatings comply with food contact regulations for America, the European Union, Japan, India and other countries. Our coating materials are formulated and applied in such a way so as to ensure regulatory compliance by being safe for food contact and for the consumer. Also, the products deliver excellent shelf-life properties and flavour performance.

AA: What is the product's chemistry?

CB: The chemistry involves acrylic, polyester, or polyolefins depending on the applications and regulatory requirements.

AA: Is the coating compatible with all methods?

CB: We offer coatings for various application methods like spraying, gravure and offset printing.

AA: What is the minimum gram of coat weight to achieve the desired results?

CB: For the internal part of a can — depending upon what is being packed, the amount of coating ranges from 4 to 14-grams per sqm of dry film weight. For the exterior application (overprint varnish), it is typically 3–5-grams per sqm.

AA: Please share the cost comparison with the normal lamination with chemical coating.

CB: Comparing costs can be challenging due to variations based on the specific end use. However while lamination technology isn’t universally applicable, conventional coatings offer cost and efficiency optimisation which has been developed over the years that they have been used.

AA: Given the cost comparison, are there any superior benefits for converters?

CB: Both coatings and laminated films have their benefits. Coatings, both epoxy and BP ANI coatings, provide excellent flexibility performance. They are able to quickly shift and perform in a variety of pack sizes and shapes. In addition, coatings have the advantage of packing a variety of packs including retort packs. Laminated films have benefits in terms of process ease and being able to be used in a wide variety of packs, and with can shapes and sizes. That said, concerns remain for the ability to pack high temperature retort packs and fills. These can change between package shapes and sizes.

AA: Any application where lamination is better suited?

CB: Yes, there may be some packs like wine in beverage cans where lamination is better suited.

AkzoNobel is planning to manufacture BPAni coatings and water-based overprint varnishes at Thane

AA: What kind of certifications do you have for your product or what certifications have you applied for?

CB: Our products comply with many regulations — they are tested in world-renowned laboratories which conform to the requirements of the United States Food and Drug Administration (FDA), EU Food Contact Material Regulations, the Food Safety and Standards Authority of India (FSSAI), China Food GB Standards, Regulation of Food Contact Materials (FCM) in Japan, and other requirements in other countries. Products are manufactured following European Printing Ink Association (EuPIA), European directives, REACH (Registration, Evaluation, Authorisation of Chemicals) and GMP (Good Manufacturing Practices) among others.

AA: Does it comply with the rules and regulations for the export market?

CB: Our products are designed, tested and manufactured for export markets. The products comply with regulations in most countries across the globe.

AA: In terms of sustainability standards, how do your coatings perform on the carbon footprint and recyclability scorecard?

CB: Sustainability is at the core of our identity — we produce durable solutions more sustainably. By 2030, our goal is to reduce our carbon emissions by 50%, and have 100% circular use of materials in our operations by reducing, reusing, and recycling. Also, we want to help our customers become more sustainable, by reducing our carbon footprint by half across our value chain. I think 50% of our revenue will come from sustainable solutions by then.

AA: What sustainability compliance does your company have?

CB: We are a recognised sustainability leader; and the only paints and coatings company with a AAA in MSCI. We belong in the top 1% of all companies assessed by EcoVadis. Also, we are the only paints and coatings company in the ESG industry, top rated by Sustainalytics.

AA: One feedback we have received from converters is that controlling the viscosity of coatings and ensuring consistency is burdensome. Your view?

CB: Controlling viscosity is critical to a consistent film and its performance. We have developed formulations and production methods over the past years to help minimise the ‘burden’ on our customers. We work with our customers so that they can apply our products for maximum efficiency in their plants.

AA: Is there a knowledge gap, or technology gap in the applicator ecosystem that can be addressed?

CB: We work closely with our customers and work together to resolve any issues that they may face in their plant which may or may not be connected with our products. Continuous knowledge-sharing, regulatory updates and conducting training sessions including in the area of product application are our key responsibilities.

AA: The share of polymers in sustainable food packaging applications is expected to fall by half over the next two decades. How is this impacting your coating R&D?

CB: AkzoNobel is developing and launching our next generation packaging coatings which perform excellently across multiple packs and processing methods. This includes retort and hot-fill, where lamination technology may be challenged. These innovations are global in nature and meet regulatory requirements across different countries in Asia, Europe and Americas.