How Edelmann optimised its pre-press due to EyeC partnership of ten years

The world’s leading manufacturer of packaging solutions made of cardboard and paper, the company Edelmann Group knows that “not all packaging is the same”. The Edelmann Group already used an automated inspection system to ensure the quality of its products in its pre-press control process. With the EyeC Proofiler Graphic, the quality of the print templates were further optimised. Abhay Avadhani reports

18 Jan 2024 | By Abhay Avadhani

With a focus on folding boxes, package inserts, rigid boxes, vial cards, system packaging, wet adhesive labels and corrugated cardboard products, the family company founded in 1913 now has a global presence with locations in Germany, Mexico, Brazil, Hungary, Poland, China and India To guarantee the best possible solutions and results, the most modern systems are deployed.

The Edelmann Group already deployed an automated inspection system to ensure the quality of its products in its pre-press control process. With the EyeC Proofiler Graphic, the quality of the print templates could be further optimised. Transferring customer data to a print template is always a delicate issue, where graphical variations and manual review processes can delay production and cause errors. Through the automated inspection of the print files, any rework and complaint costs can be prevented safely and reliably.

To continually improve the inspection process in pre-press, identify sources of error and guarantee reliable quality control processes, the Edelmann Group uses the EyeC Proofiler Graphic, a sophisticated inspection technology that can further automate the inspection process and guarantee 100 percent accuracy. In addition, the new solution is fast, efficient and secure. Simple integration into the existing workflow ensures that employees can work independently with the new system as quickly as possible.

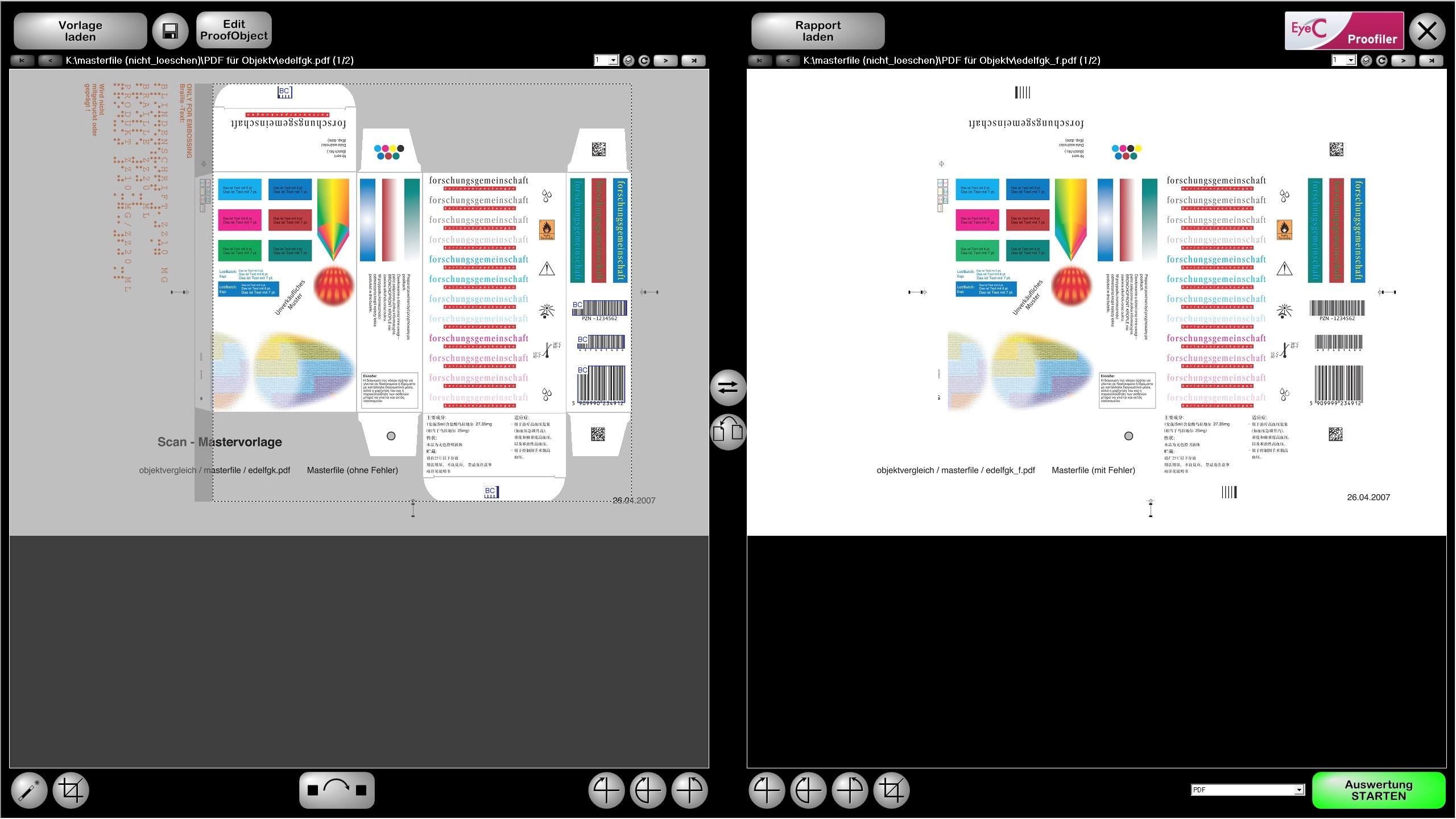

As per a tech note shared with WhatPackaging? magazine, "The smart pre-press inspection system EyeC Proofiler Graphic automatically compares the entire content of print-ready files or step-and-repeat files with an authorized print template. Unlike the human eye, the system detects every error within the print-ready PDF files. All kinds of deviations can be discovered before the printing plates are manufactured. Texts, graphics, Braille as well as 1D and 2D codes are checked graphically in just one inspection run. The inspection system automatically detects all elements in a PDF file and displays the object-based deviations to the user."

Every artwork goes through an extensive inspection before it is sent to the platesetter

Thanks to the intuitive user interface, complete inspections can be carried out in just a few steps using the EyeC Proofiler Graphic. The complete documentation of all results and the output of a comprehensive report at the end of each inspection enable complete traceability and tracking of the results.

For over 10 years, EyeC and the Edelmann Group have been working together as reliable partners in pre-press and the CTP (computer-to-plate system) for the graphic and content checking of PDF data and PDF full pages. Every new order and every artwork goes through an extensive inspection before it is sent to the platesetter. Ten multi-user licenses also enable easy access to the system by employees at international locations. In addition to the high level of userfriendliness, an Edelmann team member names the reliable support of EyeC’s service department as a decision factor.

EyeC GmbH is based in Hamburg, Germany, has been providing fast, accurate, and easy-to-use artwork and print inspection systems since 2002. EyeC ensures product quality throughout the entire manufacturing process – from the first artwork file to the finished printed product. EyeC products gives users 100% certainty about the print quality of their products such as labels, folding boxes, package inserts or flexible packaging. This avoids complaints and recalls, reduces production and material costs and optimizes quality testing. More than 3,000 EyeC inspection systems are now in use at pharmaceutical companies, printers, and manufacturers of branded goods worldwide. The company currently employees over 70 people in Hamburg and has international sales partners in more than 100 countries.

For over 10 years, EyeC and the Edelmann Group have been working together as partners in pre-press and the CTP