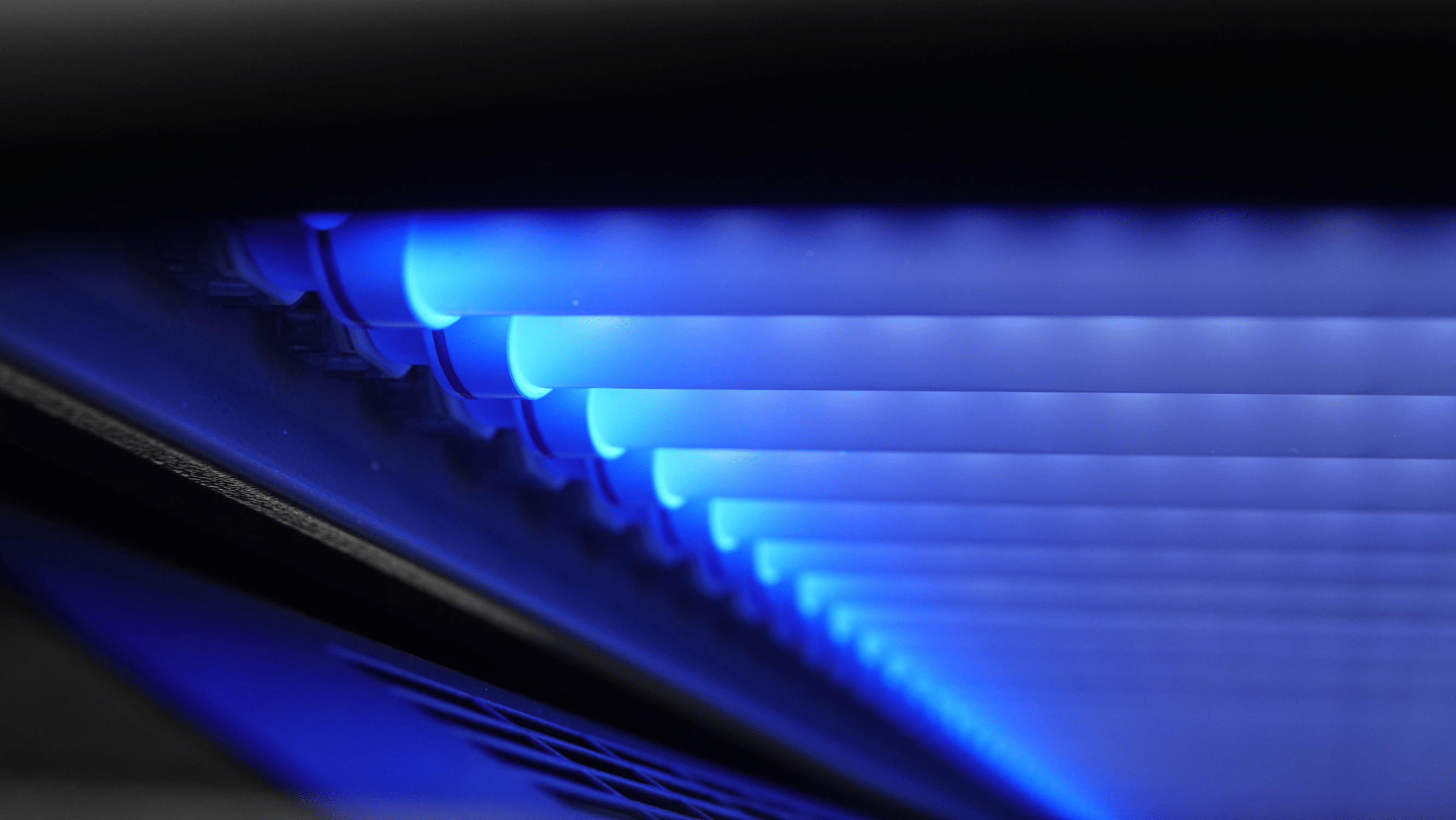

Miraclon’s Shine LED Lamp Kit: LED exposure technology for flexo plates

With the growing challenges in fluorescent-based exposure frames, Miraclon has come with an award-winning substitute known as Shine LED Lamp Kit. It aims to enable flexo trade shops and printers to gain efficiency and eliminate these challenges

18 Sep 2025 | By Abhay Avadhani

Fluorescent technology is caught in a pincer movement. On one hand, the industry is pursuing increased efficiency, sustainability and lower running costs. And on the other hand, a stream of global regulation is designed to encourage a transition from fluorescent bulbs to efficient, environmentally friendly LED lamps. This is why flexo printers and trade shops are urgently reviewing their plate exposure technology.

Problems in the plate room

The key problem with fluorescent exposure technology is inconsistent and unpredictable exposure leading to wasted time, plates and printing materials. Since fluorescent technology is more operator-dependent, plate room staff spend time monitoring bulb performance, and calibrating and recalibrating exposure units.

Fluorescent bulbs also pose environmental challenges such as being less energy-efficient than LED lamps, and generating ozone.

In addition to this, in terms of regulations, on a global scale, the Minamata Convention on Mercury, an international treaty aimed at reducing mercury emissions, has encouraged countries to begin phasing fluorescent bulbs out.

The Flexographic Technical Association (FTA) has recognised the Shine LED Lamp Kit by awarding two FTA Awards in 2024

Shine LED Lamp Kit: An alternative way to LED

To overcome these challenges ,Miraclon has innovated an affordable way into LEDs in the form of the Shine LED Lamp Kit.

The Shine LED Lamp Kit aims to enable flexo trade shops and printers to gain all the efficiency and sustainability benefits of LED exposure technology at a fraction of the cost – and without some of the challenges for a new system. It is compatible with third-party fluorescent exposure frames, as well as working with both Flexel NX and all major LAMS plates.

Andy Yarrow, regional commercial director - Asia Pacific, Miraclon, shared with WhatPackaging?, “The Shine LED Lamp Kit eliminates the frequent bulb changes, plate remakes and mercury disposal necessary with fluorescent technology, resulting in decreased waste. Sustainability is enhanced due to reduced energy consumption, with Shine LED outperforming fluorescent bulbs by up to 80%.”

With no lamp warm-up and cool down, exposure times are up to 20% faster, increasing plate room productivity and reducing bottlenecks. The uniformity of the flexo plate exposure also enables on-press efficiencies, with consistent printing and a reduction in unplanned press stops.

Andy Yarrow, regional commercial director - Asia Pacific, Miraclon

An award-winning solution

The Flexographic Technical Association (FTA) has recognised the Shine LED Lamp Kit by awarding two FTA Awards in 2024. One for technical innovation and the other for sustainability excellence. The Shine LED Lamp Kit has also won the German FTA (DFTA) Sustainability Technology Award.

Joe Tuccito, director of education, FTA, said. “The Shine LED Lamp Kit is remarkable in that it not only delivers major benefits in plate rooms and on press at low cost, but is also open to major flexo plate types and fluorescent exposure frame types from leading manufacturers.”

The jury at DFTA Awards, spoke about the importance of Shine LED Lamp Kit. They said, “Instead of having to invest in a completely new exposure system, companies can use the Shine LED Lamp Kit to convert their existing machines to modern LED technology at a fraction of the cost.”