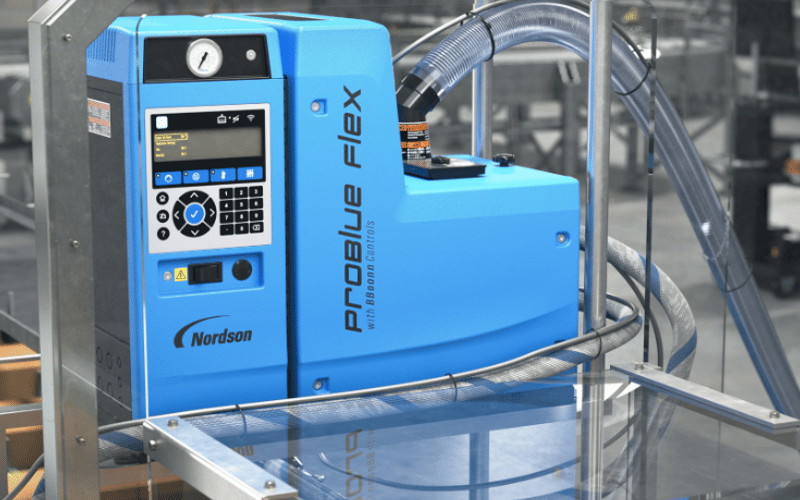

ProductWatch: Nordson’s ProBlue Flex melter

Nordson India devices modular, scalable and integrable solutions that optimise adhesive consumption and production efficiency. Aditya Ghosalkar of WhatPackaging? team finds out the ProBlue Flex melter, which offers offers flexibility, improved precision, better connectivity, and complete machine integration

18 Apr 2024 | By Aditya Ghosalkar

The modular ProBlue Flex comes with IoT 4.0 enabled hot melt adhesive melter, the EcoBead Inspect, and the Adhesive Tracking System (ATS). These features provide an optimal solution against pop-opens, downtime, and adhesive wastage.

Saurabh Gupta of Norsdson says, “The USP of the ProBlue Flex melter is the BBconn Controls platform that provides connectivity, remote accessibility and the data required to meet your continuous improvement goals.”

“The melter ensures precise adhesive dispensing with electronic pressure run-up that allows pressure to ramp up with line speed. This enables the same amount of adhesive to be dispensed for each product,” explains Gupta.

Previously, in conversation with WhatPackaging? Team, Sachin Athaley of Nordson shared that: “The ProBlue is an engineered product that is customisable to suit application needs, integrated with the latest adhesive, dispensing technology by Nordson, connected to the Internet of Things (IoT) and field upgradeable solutions.”

The ProBlue Flex also has a ‘melt-on-demand’ function which gives it a longer life due to decreased likelihood of charring, and aids adhesive saving, eventually decreasing costs. When accompanied by the Adhesive Tracking System (ATS), EcoBead Inspect and PureFlow Hose, the ProBlue Flex is equipped to deliver improved adhesive performance by reducing material degradation, trackable and therefore modifiable adhesive dispensing levels and lowered product reject rates. This is done by optimising adhesive placement on substrates thereby producing a system that pays for itself in a period of months.

The EcoBead Inspect can interface with a parent machine to generate multiple error alarms if parameters for adhesive application are not met, producing adhesive savings from 30 to over 50 % depending on the application.

And, the Adhesive Tracking System (ATS), directly measures adhesive volume, and alerts the system when the amount of dispensed adhesive is out of a predetermined band. Like with the EcoBead Inspect, it generates multiple error alarms allowing the user to correct the problem before it’s too late.

On the operation front, the ProBlue Flex system has an intuitive user-interface that makes set-up and operation effortless. The system can save up to 100 recipes that can be recalled as needed. Settings and recipes can be accessed or updated remotely through the main machine's PLC control panel, eliminating the need for operators to access the machine for change-over.

Nordson has a locally-available service network, a TrueBlue service and preventive maintenance plans, global service and distribution centres, plus repair and exchange programs.

Contact: Saurabh Gupta | +91 98105 03447 | nordsonindia@nordson.com