Day Two of ElitePlus: Business, brands, and startups focus on sustainable packaging

The two-day summit on speciality films and flexible packaging offered a panoramic view of how the industry is evolving in the face of regulatory shifts, consumer expectations and sustainability imperatives.

06 Sep 2025 | By Sai Deepthi P

Day Two of ElitePlus 12th Annual Speciality Films & Flexible Packaging Global Summit & Exhibition began with a panel discussion on capital markets for value-added diversification which featured young voices from the industry speaking about valuation, growth, and capital raising. Parth Gandhi, founder and CIO of Bombay Capital Management moderated the discussion which had voices and CEOs and founders of brands such as Growit, Canvaloop , Cool the globe, and Digital Paani.

Special video message

Deepak Mishra, joint secretary, Department of Chemicals & Petrochemicals at the Ministry of Chemicals & Fertilizers, Government of India, addressed delegates at ElitePlus Global Summit through a video message. He congratulated ElitePlus for bringing together “global leaders in flexible and rigid packaging, recyclers, converters, raw material suppliers, policy makers, NGO leaders, brand owners.”

Acknowledging the global headwinds facing plastics exports, Mishra said that this was the right time for all stakeholders to come together to consider solutions. Expressing optimism he said, “I’m sure that like all the times, good or bad, these times will also pass, probably very quickly.” He urged industry leaders to expand their horizons by seeking out new markets, opportunities and geographies, while emphasising the government’s backing for the sector.

Mishra pointed to India’s leadership in plastic packaging, citing the ban on single-use plastics and the introduction of the extended producer responsibility (EPR) regime.

Business session IV on sustainable development through innovation

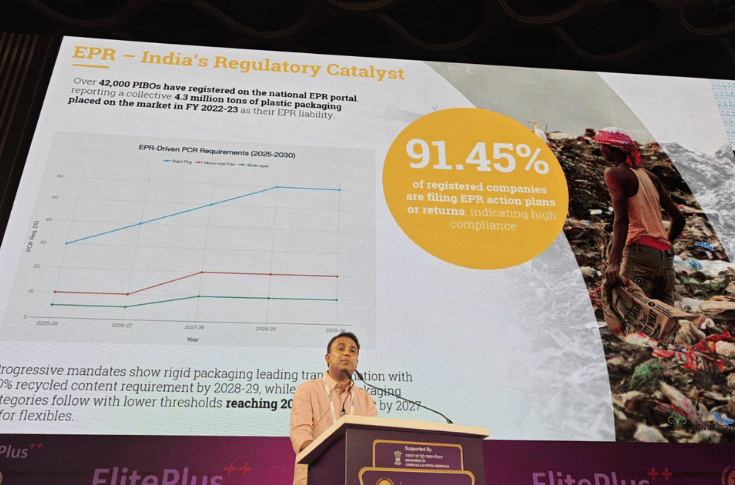

Business session IV began with Mani Vajipey, co-founder & CEO, Banyan Nation, speaking about advancing innovative and sustainable flexible film solutions. He recalled how the company had pioneered washing technologies that enabled billions of packages across India to be made from recycled plastics.

With that foundation, Banyan Nation is now expanding its expertise into flexible films, punches and other segments, while maintaining its broader vision. He observed that Extended Producer Responsibility (EPR) had fundamentally altered industry behaviour: the informal sector had begun adopting segregation techniques, while brand managers had moved from debating whether recycled content was necessary to asking how much and when it could be deployed. In flexible packaging, the industry faces three technical barriers: odor migration that risks entire batches, persistent ink systems, and adhesive contamination. These, he argued, were exactly where Banyan had an advantage. Having resolved similar challenges in rigid packaging, the company had completed proof-of-concepts across sectors and invested in a sophisticated material characterisation lab.

The summit came full circle when one of Banyan Nation’s clients, Aishvarya Murali, founder of Tuco Kids, appeared on the final panel of the day on Day 2 and credited Banyan Nation with helping her start-up adopt fully recycled plastics from the outset, instrumental in building Tuco Kids’ brand identity.

Business session on brand owners and converters - innovating for consumer delight

The fifth business session of the summit, brought together four speakers representing FMCG majors, adhesive and coating specialists, film innovators, and liquid packaging pioneers.

Shuvadip Banerjee, ITC, spoke about ITC’s FMCG journey since 2002, noting that region-specific product development and trend-led innovation were key drivers of growth. He cited the example of how ITC’s instant noodles, deliberately differentiated from Nestle's Maggi through round shapes and Indian flavours, to create impact. He warned that with attention spans shrinking, reliance on advertising alone was no longer viable; brands had to build experiences tailored to new consumer value systems.

Sunil Kumar from Henkel India, outlined Henkel’s focus on adhesives and coatings that enable recyclability and circularity, including Henkel innovations in labels, caps, and multilayer alternatives.

Naomi Lunadei from Toppan Speciality Films stressed the need for mono-material solutions, presenting Toppan’s developments from S-BOPP to BOPE and barrier films.

Subodh Kulkarni of Tetra Pak India explained Tetra Pak’s sustainability agenda, including paper-based barriers, recycled polymers, and annual EUR 40-million investment in recycling. Kulkarni mentioned that Tetra Pak was the first to introduce cartons with 5% recycled plastics. He added, "We are designing our packages such that our customers have a high product-to-packaging ratio of 96:4." He told the gathering, "We have already started using certified recycled polymers, and we are testing paper-based barriers."

Panel discussion: Plastics in circularity

The sixth session on plastics in circularity was moderated by Jeevraj Pillai, director of sustainability and president – flexible packaging and new product development, UFlex. Professor Vimal Katiyar from IIT-Guwahati opened the discussion by reminding the audience that plastics are a valuable material but require responsible post-consumer waste management, reduction of over-engineering, and indigenised ecosystems to ensure safety.

The panel included Sidharath Behl of SRF, who emphasised readiness to support PCR targets and the importance of traceability; Ankit Singhai of Nestle, who underlined the company’s carbon neutrality and called for greater clarity on multilayer substrates; Vishal of Mondelez, who highlighted the need for recyclability-by-design; Aditya Dalmia of Dalmia Polypro, who spoke of FSSAI-approved rPET and cost-related adoption hurdles; Ashish Saxena of UFlex, who pointed to innovations such as a single pellet solution and stronger polyester films; and Bipin Odhekar of Marico, who stressed caution when dealing with food-grade applications.

Collectively, the panel highlighted that while India is prepared with technology and regulatory frameworks, adoption will depend on cost efficiency, design innovation and collaboration across the value chain.

Business session: Innovating printing, automation, lamination & winding

The sixth business session on innovative printing, automation, lamination and winding showcased advances across digital printing, converting, slitting and gravure.

Appadurai A of HP India Sales positioned HP Indigo as a more sustainable alternative to conventional print, citing reduced pre-consumer waste and greater flexibility for brands. With more than 300 presses installed in India, HP Indigo’s footprint spans from boutique converters to industrial operations. The ability to handle multiple substrates and meet fast turnarounds stands out. "Our customers value speed and quality," Appadurai said. The company’s growth stems from this consistent alignment with the expectations of the flexible packaging industry.

Yash and Vasu Shrimanker of Pelican presented the Pelican SmartPress, highlighting improvements in web handling, energy efficiency and intelligent automation to reduce solvent usage and emissions. The two siblings alluded to the operations in Pelican's 24-acre manufacturing plant, and how the order book is busy because of installations in Indian and across the globe.

Biku Kohli and his team from SP Ultraflex marked the company’s 40th year with automation-led solutions such as the Ultraslit Max OHP, Duplex Trim Winder and Roboslit Plus, underscoring a growing reliance on automation.

Closing the session, Davide Garavaglia of Bobst, Italy, introduced SmartGravure and the Master RS 6003, both fully automated gravure presses designed for repeatability, colour consistency and profitability, alongside intelligent metallising assistants driven by vision technology.

Panel discussion VII: Adoption of circular economy models

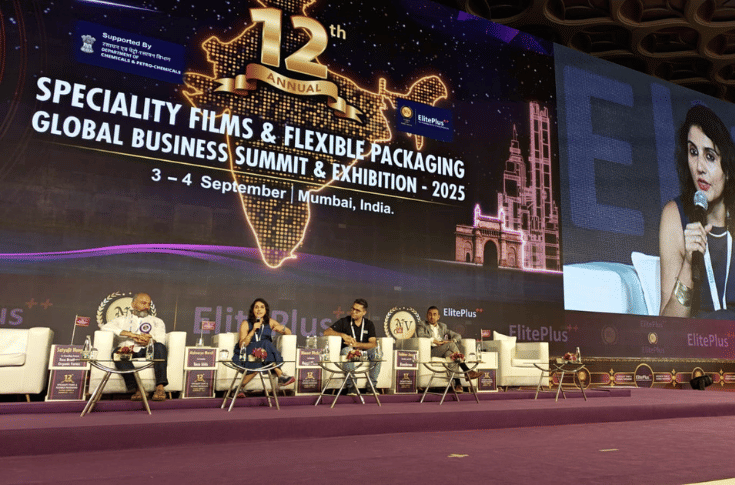

The final panel of the two-day summit addressed the adoption of circular economy models in packaging, bringing together new-age brands that have sustainability at their core.

Satyajit Hange of Two Brothers Organic Farms explained how sustainability runs through every aspect of their brand, from seeds to packaging, and how switching to glass bottles led them to work with Korigami Packaging on cardboard supports.

Aishvarya Murali of Tuco Kids described the challenges of developing recycled plastic packaging in partnership with Banyan Nation, navigating thickness, colour variation and transparency while ensuring brand identity.

Nimeet Dhokai of Happi Planet outlined how homecare products in paper cartons gave the brand a distinctive edge with consumers despite shipping challenges.

Vaibhav Anant of Bambrew emphasised the need to solve for primary packaging through bioplastics that match the functionality of virgin plastics while running on existing machinery. The founders collectively urged large packaging companies to make off-the-shelf, monomaterial, 100% recycled solutions available to emerging brands, highlighting the need for collaboration to accelerate adoption.

Across two days, the summit laid bare the sector’s dilemmas and its opportunities. On the one hand were entrenched challenges of fragmented supply chains, high costs and technical barriers. On the other stood breakthroughs in recycling, digital printing, adhesives and automation, coupled with the conviction of emerging brands.