Rethinking flexible packaging for a sustainable future: A session by Robert Cotton

Cotton stressed that biodegradable packaging is not a universal solution, but it has important advantages.

08 Sep 2025 | By Sai Deepthi P

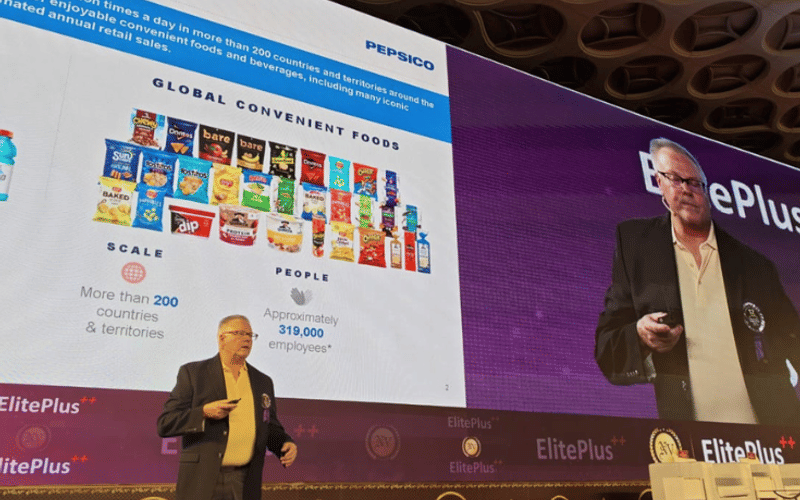

Robert Cotton, R&D director - packaging sustainable materials, PepsiCo, presented on day one of ElitePlus 12th annual speciality films & flexible packaging global summit & exhibition. He spoke about sustainable packaging at PepsiCo.

Cotton outlined efforts to invent new materials, work with industry partners, and build packaging solutions that can be adapted across PepsiCo’s global operations.

Having worked in the field for 35 years, Cotton stressed that scale brings responsibility. Flexible packaging, he argued, is already one of the most efficient forms of packaging, using the least material per gram of product. However, this efficiency creates a challenge because flexible packs are rarely collected and recycled, leaving them without a clear end-of-life pathway.

Cotton outlined PepsiCo’s three pillars of packaging sustainability. The first is reduction: using less material without compromising on appearance or function. The second is recyclability: developing films that can be collected and reprocessed. The third, closest to his own interests, involves biodegradable films and recyclable paper-based alternatives. Each pillar reflects a recognition that no single solution will be sufficient, and that packaging must be tailored to the regulatory, infrastructural, and cultural context of each market.

On recycling, Cotton acknowledged that circularity is a widely shared vision but remains elusive in flexible packaging due to limited infrastructure. Extended producer responsibility schemes, now being introduced in many countries, are beginning to address this by funding collection and sorting systems. PepsiCo’s R&D teams are actively designing solutions to fit varied legal frameworks while maintaining food safety. Reducing virgin plastic use remains a top priority, but only when suitable alternatives are available and proven.

Cotton then turned to paper. For decades, plastics replaced paper in food packaging, yet consumer sentiment has swung back in favour of paper, making it a desirable material once again. The main obstacle is creating an adequate moisture barrier. As he noted, paper is only functional when combined with plastics, which undermines recyclability. Furthermore, most of PepsiCo’s manufacturing relies on vertical form-fill-seal machinery, which presents additional complications when working with paper. Multipacks, such as secondary packaging for small snack bags, offer the most immediate opportunities. In the UK, for example, Quaker oatmeal already uses paper packaging, though it is not recyclable. The company is now developing alternatives that can claim recyclability while still meeting performance and branding requirements.

He praised recent industry advances such as dispersion coatings, extrusion coatings, metallised paper, and improved machinery capable of handling both plastics and paper. One promising interim solution is laminating thin metallised OPP film onto paper, creating structures light enough to claim recyclability under European standards. However, sealing and forming these structures without losing barrier performance remains a challenge, requiring innovations such as heat-seal coatings and new sealing jaws.

Cotton characterised this as a step in an ongoing journey, rather than a final solution, with future progress likely to combine coatings, metallisation, and evolving paper technologies. He then highlighted how biodegradable films, particularly polyhydroxyalkanoates (PHA) and blends with PBAT, PLA, and PBS. He recalled PepsiCo’s 2009 launch of a PLA-based snack bag for the SunChips line in the United States, which was ultimately phased out. The experience underscored both consumer expectations and the potential of biopolymers.

In partnership with Kaneka in Japan and equipment makers such as Bruckner, W&H and Reifenhauser, PepsiCo has developed structures that can be processed on conventional polyethylene equipment. The resulting films, rich in PHA, meet stringent home compostability standards, including 90% biodegradation within six months, continued breakdown beyond that point, full disintegration into smaller pieces, and absence of ecotoxicity. Even inks have been certified as safe, while ultra-thin metallised layers degrade harmlessly into aluminium oxide.

Cotton stressed that biodegradable packaging is not a universal solution, but it has important advantages. It can complement existing end-of-life systems such as anaerobic digestion and landfill management while also addressing the issue of mismanaged waste that leaks into the environment. To strengthen research, PepsiCo has even built a greenhouse at its Dallas R&D centre to conduct biodegradability tests. In the final part of his remarks, he noted that the most difficult work is no longer technical but political and commercial.