Fast-growing packaging factory illuminates solar revolution

PR Packagings is a 30-year-old packaging manufacturer specialising in printed primary, secondary, and tertiary packaging. Located on nine acres of land, the company provides a one-stop solution for clients seeking to source products from India. With a team of 350 people, PR Packagings turnover is INR 100 crore, with a CAGR of 8% to 10% per annum. WhatPackaging? magazine caught up with Vishesh Gupta, executive director of PR Packagings, to discuss the solar journey.

29 Jul 2025 | By Prabhat Prakash

PR Packagings, a leading packaging converter based in Faridabad, has ramped up its commitment to sustainable operations, reaching 1.1-megawatt (MW) total solar energy capacity. Vishesh Gupta, executive director at PR Packagings and an Indian Institute of Technology (IIT) Kharagpur alumnus, provided insights into the company's multi-chapter journey towards solar adoption.

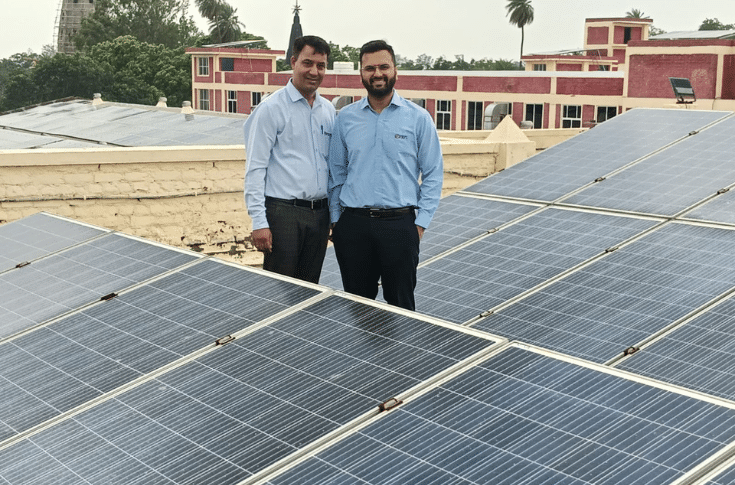

"The solar story began in chapters, with installations of 125-kilowatt (kW) in 2018, 150-kW in 2021-22, and a significant 875-kW in 2024-25, bringing our total to 1.1-MW today," Gupta states. He describes the installation process, handled by Ricans Solar, as remarkably smooth for an industrial infrastructure project, quipping, "It’s rare to say that about any industrial infrastructure project, but here we are. Perhaps the sun was already on our side."

Currently, PR Packagings generates approximately 1,400-egawatt-hour (MWh) annually from its solar array, effectively covering over 25% of its peak operational needs and reducing its dependency on the grid by 20-25%. Gupta emphasised the essential nature of sustainability, noting that while tier-1 brands generally appreciate such efforts, for most tier-2 companies, it primarily earns "brownie points" rather than directly influencing purchase orders.

PR Packagings is a horizontal facility spread across nine acres, perfect for both solar panels and Sunday morning walks. The sun shows up, the PR Packagings machines hum, and nature pays the electricity bill

Efficiency through solar installation

Given that power and energy represent a major cost component for packaging converters, the financial rationale behind this investment is compelling. Gupta explains, "Electricity typically accounts for 4% to 6% of operating costs for most converters." He added, "In an industry where margins are thinner than the laminate on a five-layer tube, even a half-percent saving is worth celebrating, preferably under LED lights, not halogen hopes."

While Haryana has not introduced direct tax incentives for rooftop solar, unlike states such as Gujarat or Delhi, it does offer other benefits. Gupta confirmed that Haryana has waived electricity duty, wheeling charges, and transmission fees. The 200,000-sq-ft factory roof, spread across nine acres, proved to be an ideal canvas for the solar panels. The company opted for a direct capex (capital expenditure) model for the most recent phase of solar installation, having previously utilised a PPA (power purchase agreement) model for earlier setups.

Gupta estimated the ballpark figure for a mid-sized firm to invest in solar at roughly INR two-crore for 875-kW, suggesting a PPA model for those unsure about upfront investment. He recommended a PPA model for businesses hesitant about upfront capital investment, explaining, "We opted for a direct capex model in the recent phase. In earlier ones, we followed a PPA model, a 25-year power purchase agreement with ownership transfer after the term." This hybrid approach ensures continuous operation; solar panels manage the load on sunny days, with the DISCOM (electricity distribution company) taking over during cloudy periods.

Commitment to sustainability

PR Packagings commitment to sustainability extends beyond solar energy. The facility operates as a zero-discharge plant, incorporating in-house sewage treatment plants (STP), effluent treatment plants (ETP), and rainwater harvesting systems. The entire plant is illuminated with energy-efficient light-emitting diode (LED) lighting. To streamline logistics and manage waste, the company has installed an independent weighing bridge. Daily food waste is meticulously monitored and bio-composted, contributing to a one-acre green garden tended by three full-time gardeners. "It’s not just for show," Gupta remarked. "That green patch improves temperature regulation, ambience, and sanity... a much-needed pause in the middle of production chaos." All paper scrap generated is responsibly recycled through official partners.

The Guptas' mantra at PR Packagings: If you have a roof and a long-term view...go solar. It's one of the few business decisions where nature and numbers shake hands

Gupta expressed high satisfaction with the tangible results of their solar investment, confirming that solar now generates 25% of their total energy, leading to annual savings of INR 80 to 85-lakh. He strongly advocates for solar adoption by other businesses aiming to reduce their carbon footprint and long-term energy costs, asserting that it is "one of the few business decisions where nature and numbers shake hands."

Growth through strategic investments

Gupta says, "At PR Pack, we’ve always believed that leadership isn’t just about running a factory — it’s about leaving behind a better one." He owes his vision to his parents (Ravinder Gupta and Punita Gupta), who built this company with values stitched as tightly as any 5 ply - 7 ply carton on our line. Gupta adds, "Becoming a father of two recently has deepened that perspective. It’s taught me that real progress isn’t measured in sudden spikes or overnight scale, but in steady, principled steps... built to last, not just impress. Growth, like good packaging, must be durable, ethical, and mindful of what it holds."

"With the new corrugation setup, our output has increased more than triple with the same manpower and lower consumption of electricity. Thus, we can save on both manpower and electricity. For heating the rollers, we had two options: thermic oil or steam boilers for heating. We opted for thermic oil because the anticipated product mix of fluted cartons is not high enough to justify the installation and operational cost of a boiler," Gupta says.

Right now, the company is producing lamitubes, leaflets, mono cartons, printed fluted cartons, rigid boxes (top, bottom, foam inserts, top flap) for all sectors, including pharmaceuticals, electronics, food, FMCG, and industrial. Gupta says the company would like to establish itself as a one-stop solution provider that can cater to the packaging requirements in key segments. He says, "It’s never just about what you deliver. It’s about how responsibly you wrap it."

Gupta shares his belief that leadership involves leaving behind a better factory, with real progress measured in steady, principled steps that are durable, ethical, and mindful. Gupta's final words are, "We now generate 25% of our energy through solar, saving INR 80 to 85-lakh annually. In a world of rising costs, it is sunlight that pays dividends." We concur.