The quiet revolution of the MSMEs in the Indian bottled water industry

A panel discussion at the PackMach Asia Expo and DrinkTec India 2025 featured seven MSME leaders in the bottled water industry to discuss changes, opportunities, and challenges in the industry.

19 Dec 2025 | By Jiya Somaiya

The packaging landscape for India’s bottled water industry is undergoing a period of radical transformation, driven by shifting consumer preferences and a tightening regulatory environment. During a panel discussion on 14 November at the PackMach Asia Expo and Drinktec India 2025 in Mumbai, industry leaders gathered to discuss the road ahead for MSMEs in India’s bottled water industry.

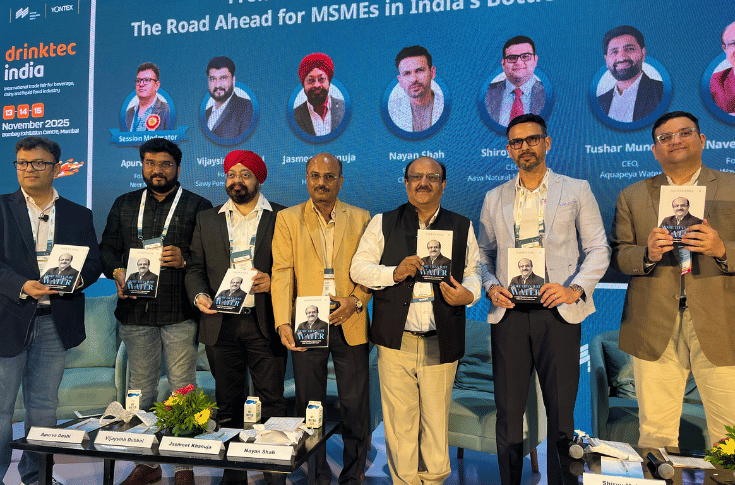

The session was led by moderator Apurva Doshi, founder of Neer Nation, and featured a group of six panellists, including Vijaysinh Dubbal of Savvy Pure Aqua, Jasmeet Khanuja of Health Plus, Nayan Shah of Clear Water, Shiroy Mehta of Aava Natural Mineral Water, Tushar Mundada of Aquapeya Water, and Naveen Goel of Wave Water.

The panel discussion turned into a book launch, as Goel launched More Than Just Water at the expo

With the global bottled water sector valued at approximately USD 351.9-billion in 2024 and projections indicating significant growth in the coming years, with some estimates for 2025 reaching USD 378.29-billion, the industry is forecasted to reach USD 674.8-billion by 2033.

Indian MSMEs are shifting their focus from basic packaging to complex material science and high-volume production. This follows the accelerated expansion within the Asia Pacific region, propelled by urban development and a greater focus on wellness, bringing Indian manufacturers to a pivotal moment.

As demand surges, the sector is moving away from its fragmented roots towards a regulated, high-tech environment where the bottle is designed as a sophisticated technical solution.

Market unity and ethical competition

The discussion — kick-started by Apurva Doshi — opened with a focus on the structural integrity of the market and was led by Vijaysinh Dubbal, who is the founder of Savvy Pure Aqua and also serves as the vice president of Federation of All India Packaged Drinking Water Manufacturers Associations (FIPMA).

Dubbal addressed the fragmented nature of the 20-litre jar segment, a core component of the MSME business model. He emphasised that for small manufacturers to remain competitive against global brands, MSMEs must move past destructive “rate wars” and focus on fair pricing and unity.

Dubbal argued that while brands invest heavily in marketing, MSMEs must leverage their collective strength to ensure that margins remain sustainable despite rising costs. He noted that a “warrior spirit” is required to navigate systemic challenges, but the ultimate path to profitability lies in healthy competition and a unified platform that prioritises quality over undercutting rivals.

Material science and the rPET mandate

The conversation regarding technical evolution was led by Jasmeet Khanuja, founder of Health Plus, who highlighted the transition from traditional corrugated cartons to shrink-film for logistical efficiency.

Khanuja pointed out that the industry’s most significant packaging challenge lies in the next 18 months: the mandatory integration of recycled PET (rPET). With government guidelines potentially requiring up to 80% recycled content in the coming years, Khanuja warned that MSMEs must begin preparing for the high costs and infrastructure changes required to handle these materials.

This shift is essential for transitioning from the unorganised sector into an organised, high-speed manufacturing environment — a move further supported by the reduction of GST from 18% to 5% on key packaging components.

Regulatory rigour and the FSSAI shift

The regulatory framework for packaging has been fundamentally altered by the FSSAI’s recent decision to omit the mandatory Bureau of Indian Standards (BIS) certification mark in favour of a “high-risk” food classification.

Naveen Goel, founder of Wave Water, who is also senior vice president of FIPMA, emphasised that this shift places more weight on the manufacturer’s internal scheme of testing and facility standards. Goel noted that for MSMEs, achieving a Central FSSAI License — which involves mandatory pre-license inspections and 5-Micron Positive Air Handling Systems — is the ultimate signal of trust for institutional clients.

This technical rigour ensures that the physical bottle is a verified, sterile environment that meets the highest safety standards for the 150-crore people living in the subcontinent.

Structural innovation as brand identity

Nayan Shah, the founder of Clear Premium Water, provided a masterclass in using structural packaging to bypass traditional branding costs.

Shah’s success in growing an INR 449-crore brand was anchored in the introduction of the square bottle and vertical labelling, a bold move that disrupted a market dominated by round containers. He argued that for an MSME, the bottle’s shape and label orientation are the primary tools for securing market space.

Similarly, Tushar Mundada, CEO of Aquapeya Water, spoke about his experience with national entrepreneurial platforms, stressing that a brand’s digital presence must reflect its physical packaging innovation.

Mundada noted that MSMEs must treat their brand as a shield, allowing them to convert a standard commodity into a premium-priced asset through perceived quality and modern design.

Sustainability and the circular economy

The future of the industry was framed through the lenses of sustainability and inclusive innovation. Shiroy Mehta, CEO of Aava Natural Mineral Water, highlighted how early adoption of glass bottles and dedicated recycling programmes (which Aava has run since 2015) allowed his firm to thrive in the eCommerce sector.

Mehta argued that in a country with acute water stress — where India is the world's largest extractor of groundwater — packaging must be part of the solution.

Ultimately, the panel concluded that for India’s MSMEs, global competitiveness is about the ability to navigate complex material mandates, utilise innovative structural designs, and maintain an unwavering commitment to the rigorous testing standards that define modern, high-quality packaging.